Brands: Additional Resources and FAQ

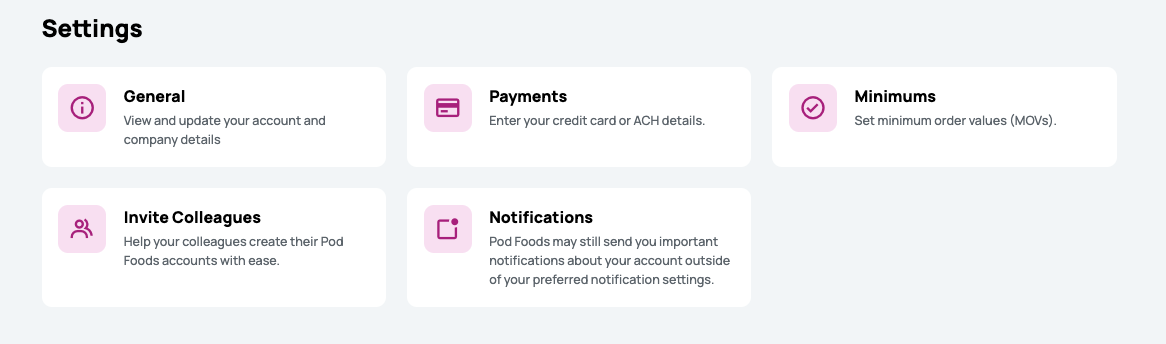

Manage your dashboard settings

Company information related to:

Your contact information

COI and W9 forms

General company information and document upload section (i.e. product certifications)

MOV - Minimum Order Value. This ensures that retailers can pick and choose across multiple product lines to meet your dollar-value-minimum for Pod Direct.

MOQ - Minimum Order Quantity – the MOQ that is set on the individual Product page applies to minimum case quantities per product. For instance, if it only makes sense for you to ship in quantities of four cases, you may elect to set the MOQ along with, for example, a $1 MOV.

When selecting a minimum - MOV will allow for a fixed dollar amount by region addressable within the same window. Setting an MOQ will require you to return to the unique SKU and apply a casepack minimum per SKU. Please use these instructions to manage your SKUs.

Help your team members create their Pod Foods account with ease

Adjust your in-app and email settings

A case is a wholesale purchase unit that contains a specified quantity of the SKU units being sold. While you determine the number of individual units per case (units/case), there are industry standards based on the type of product. Standard cases are usually an even number of units (6, 8, 12, 24).

Case packs offer ease in transportation, storage, and receiving processes. Each case should be clearly labeled as detailed below. Clearly printed labeling on both cases and units is critical.

Many warehouses and stores, especially chains, will not accept products that are not contained within casepacks. Packaging should hold and protect the product as it travels through several hands. If you are shipping multiple cases, they should be labeled in sequence (1 of 2 or 2 of 2). It is best practice to place sellable, multi-unit casepacks inside a larger shipping box for protection during transit.

All casepacks must have on the outside:

Number of units inside case + total case weight (unit weight x number of units)

Scannable UPC barcodes

Printed directly on the box or as an attached label. See below for examples.

Expiration dates

Should be in U.S. format: MM/DD/YY or MM/DD/YYYY.

Must be clearly marked on the outside of each carton and on every individual unit

Each individual unit should have the following printed directly on the packaging:

Unit weight

Nutritional information

Ingredients

Scannable barcode and UPC number

Use by/Best by date

Refrigeration requirements (if applicable)

Certifications (Organic, Non GMO, Kosher, etc.)

Please refer to this guide if you are scaling into Pod Express and have questions related to pallet building

Activated Pod Express brands require inventory management as they are carried in our DC network. For brands that are carried in an anchor account, or that have specific questions related to inventory, please reach out to your dedicated category manager or [email protected]

One of the key differences between Pod Foods and conventional distribution is our inventory management and requests. Pod Foods regularly requests inventory from our brand partners to maintain sell-through volume with our retail partners rather than issuing a purchase order. As inventory is received, orders are placed, and payouts are processed with net30 terms - completing the flywheel. It is essential that brands are an active partner in managing healthy inventory levels by fulfilling requests in a timely manner.

NOTE: We strongly recommend instituting an inventory MOQ which will help ensure optimal fill rates. Please reach out to your dedicated category manager or [email protected] for help setting up an inventory MOQ.

Click the “Inventory” tab in your vendor dashboard. This will present the main inventory page that details:

All Inventory

Inventory Status - Be sure to review by region for replenishment and sales insights

Send Inventory

Withdraw Inventory

Dispose / Donate Inventory

This is a detail of all inventory that is carried or has been carried in our DCs and tracked by lot codes

Received quantity

Total inventory that has arrived on consignment.

Current quantity

Total inventory currently physically on hand at distribution center.

End quantity

Quantity left once all pending orders have been fulfilled.

Pulled quantity

Quantity pulled when it can no longer be sent to retail.

This tool provides an at-a-glance assessment of your inventory health in each DC. It is strongly recommended to input an inbound inventory MOQ to ensure that safety stock is maintained and that fill rates are healthy. If you have any questions or would like to input an inbound inventory MOQ please reach out to your category manager or [email protected]

Green

You have sufficient amount of inventory at Pod Foods distribution center.

Orange

This inventory is running low. Please get in touch with our team to send more inventory to the distribution center.

Red

Insufficient inventory to fulfill pending orders. Please get in touch with our team to send more inventory to the distribution center.

This section is essential to understanding your sell through and minimum inventory threshold requirements.

Please review by the specific regions your items are warehoused in for insights to:

WEEKS OF SALES - This is an estimate to how many weeks of sales your current inventory by SKU has within the DC based on historical sell through rates

LOW INVENTORY THRESHOLD - This is the minimum casepack count by SKU for healthy fill rates

STATUS - This is color coded and indicates healthy inventory levels (green), low inventory levels where replenishment is needed (orange), or insufficient inventory and risk of out-of-stocks (red)

We highly recommend instituting an inbound inventory MOQ to maintain healthy fill rates. Please email [email protected] to get one set up if you haven't already.

This is where Pod Foods will provide inventory requests to your team. Please use this page to confirm inventory requests and track their status to our DCs. Please confirm inventory requests within one week of receiving them to maintain healthy fill rates.

Requested inventory will generate in the [Requested] tab and vendors are expected to review and approve the request within seven days to maintain optimal fill rates. Optimal fill rates are essential to your success as a brand.

Any instructions related to warehouse appointments are located in the inventory request. If the vendor wishes to add to the case counts, please email [email protected] and cc your category manager or [email protected] and we will review your adjustment request.

Pod Foods strongly recommends utilizing the Pod Freight program for inbound inventory. If you are interested in this please click here or email [email protected] and cc your category manager or [email protected]

When withdrawing inventory, use this page to submit a withdrawal request. Each withdrawal request requires a pickup appointment.

Please refer to Product + Pricing Changes

Item Codes are a unique identifier for SKUs that helps retailers search products and order with ease.

You can find your Item Code in your Vendor Dashboard > Products > SKUs > Item Code number is listed under each individual Published SKU (example: #17305)

Download detailed sales data when you navigate to Orders > Fulfilled Tab > Export > Order Details in your Vendor Dashboard. Orders are not sales. Sales payouts are initiated on the 10th of the month after an order is fulfilled.

Download detailed payments data when you navigate to Payments > Monthly Statements > Month > Export in your Vendor Dashboard.

When these reports are requested they are emailed as an attachment

We’re here to support your growth.

Need money for a new production run or to pay off business expenses? To support your growth, we have launched Pod Foods Capital where you can apply for easy and affordable financing through a few simple steps via your dashboard. Click here to find out more and get access to capital now!

Vendors may submit a claim via the dashboard

Retailers can submit a claim here

Please contact [email protected] if you have any questions

Email [email protected] to give your 60 day notice required before closing your account. A representative will follow up with you to provide next steps.

Orders are marked as fulfilled when a POD is confirmed by our team. This can take up to 10 business days from ship date. Please see our Order Fulfillment Compliance Policy for additional information.

Brands are able to set their own wholesale pricing. For additional information please see our regional pricing section.

Please refer to Vendor Payout Information

Please refer to Pod Direct Order and Payout Policy