Brands: Inventory

Everything related to inventory and freight

PHYSICAL SETUP

An overview of packaging, labeling, and shipping per Pod policy.

You and your team work hard to create amazing products! The last thing you want is for your inventory to

arrive damaged or to be rejected at receiving.

Luckily, Pod has your back! Our requirements ensure your goods arrive at our DCs safely and retail-ready.

Before you ship, make sure your packaging and labeling meet the simple specifications on the pages

and topics that follow:

PACKAGING

Your guide to Case Packs and Master Cartons.

WHAT’S A CASE PACK?

A Case Pack is a sellable wholesale unit distributed to retailers by Pod. Case Packs are required.

Before you ship, we recommend your Case Packs meet the following requirements to minimize damage incurred via transit and handling. If Case Packs do not meet the following requirements they must be packed in Master Cartons and your Master Carton details must be set up correctly in your Vendor Dashboard.

Case Packs not shipping in Master Cartons should be:

Strong enough to ship on mixed pallets of goods, no exceptions.

Able to withstand a 3 ft drop test. The box is dropped from 3 ft, once per side and once on a corner. No damages occur as a result of the drop.

The box has 6 sides.

The box does not collapse under medium pressure

Able to withstand exposure to dirt and dust in warehouse and shipping environments

The box is labeled correctly (see below for labeling best practices)

Boxes (caddies, displays, etc.) that do not pass the above-mentioned requirements must be

shipped in a standard single-walled secondary cardboard box.A standard single-walled secondary cardboard box will be referred to as Case Pack and must be

labeled as such.There can be more than one box (caddy, display, etc.) in a Case Pack; the Case Pack is the sellable

wholesale unit.

WHAT’S A MASTER CARTON?

A Master Carton is a large, secondary box containing Case Packs that needs to be broken down

before distribution to retailers. Master Cartons are optional.

If you ship in Master Cartons, your Master Carton must:

Be labeled as a Master Carton, otherwise, it will not be broken down.

Be set up as a Master Carton on your Dashboard.

Contain only a single SKU.

LABELING

Make sure your goods are properly labeled.

UNITS

Must be clearly labeled with the following:

Lot Code and Expiration Date*

UPC + Scannable Barcode (Unit UPC)

Units MUST be labeled with expiration date displaying month, day, year in readable format.

CASE PACKS

Must be clearly labeled with the following:

Brand Name

SKU Name

UPC + Scannable Barcode (Case UPC)

# Units per Case Pack

Lot Code and Expiration Date*

Total Case Pack Weight

Storage Temperature (if any)

Handling Requirements (if any)

Country of Origin

Case Packs MUST be labeled with expiration date displaying month, day, year in readable format.

MASTER CARTONS

If shipping in Master Cartons they must be clearly labeled with the following:

“Master Carton” explicitly stated

Brand Name

SKU Name

UPC + Scannable Barcode (Master Case UPC)

# Units per Case Pack

# Case Packs per Master Carton

Lot Code and Expiration Date*

Total Case Pack Weight

Storage Temperature (if any)

Handling Requirements (if any)

Country of Origin

Master Cartons MUST be labeled with expiration date displaying month, day, year in readable format.

PREPARING SHIPMENTS

The must-know nitty-gritty on shipping pallets & parcels.

PALLET REQUIREMENTS

Minimum Requirements

ISO-approved pallet

Standardized pallet dimensions (stringer length x deck board width):48” x 40”42” x 42”48” x 48”

60” maximum stack height

Hardwood or plastic

Minimum 2500 lb capacity

Good quality (no damages)

Recommended:

GMA-spec pallet

4-way entry

Hardwood

48” x 40” dimensions

Subject to Rejection:

Metal

Damaged, poor-quality

Non-ISO-approved

Single SKU Handling

Our warehouses do not accommodate multiple lots for a single SKU on inbound shipments. Sending multiple lots for a single SKU is not approved and will incur additional fees, in addition to the standard pallet handling fee.

Separation of SKUs

For pallets containing multiple SKUs, each SKU must be logically grouped and clearly separated and labeled from the others.

Use adequate spacing, slip sheets, or cardboard dividers (recommended) to maintain clear separation and prevent mixing of SKUs.

Use of Multiple Pallets

If shipping a large number of SKUs or large quantities, use separate pallets for each SKU whenever possible to simplify handling and identification.

Clear Labeling

Ensure that each SKU is clearly labeled. Labels must be securely attached and face outward for quick and easy visual verification upon receipt. Proper labeling and grouping will help avoid any additional warehouse sort & segregation charges.

PALLET SHIPMENTS

Configuration and integrityPallets must be configured to maximize space and strengthNeed a few tips for building your best pallet? See our Pallet Building Guide.No overhang may exist beyond the pallet’s perimeterCases are sealed and are in good conditionCornerboards and slipboards are presentPallets with excessive case damages due to improper case stacking will be refused.

Pallet wrapping

Shrinkwrapped/stretch-wrapped pallets must be wrapped using clear/transparent plastic material.

Pallets wrapped in opaque material will be rejected at receiving.

Pod Inbound Label

Must be present on side of pallet

A packing list must be included within the shipment. Packing Lists can be downloaded within the Inventory Request under the Inventory => Send Inventory tab of your dashboard.

Additional labor charge:

Sort and segregate fees may apply to inbounds that arrive with significant damages or arrive as mixed pallets.

These charges are in addition to the standard $30 handling fee for multi-SKU pallets.

Labor fees will apply for products that are mislabeled and require relabeling.

PARCEL SHIPMENTS

Shipments with more than 10 retail cases are not permitted to be sent via small parcel unless approved in advance.

Parcel shipments have a receiving lead time of 14 days (vs 2 day receiving lead time for LTL).

Here are the key requirements for parcel shipments:

Parcel shipments must be authorized by our inventory team at inventory@podfoods.co.

Parcels must contain a Pod Information Label on the outside and include a packing list.

If sending multiple parcels, please label each case clearly (e.g., case 1 of 3).

Shipments should not exceed 10 retail cases or weigh more than 100 lbs in total.

Shipments must be sent via USPS, UPS, or FedEx.

Please note that parcel shipments incur a handling surcharge of $5 per retail case.

Parcel shipment is for dry goods only and is not suitable for time-sensitive frozen items.

Our strategic freight partners offer competitive rates. For a freight quote, please reach out to inventory@podfoods.co.

Your commitment to transition to LTL is essential to prevent future shipment refusals or delays.

SHIPPING + FREIGHT

Getting your inventory to our DCs is a breeze.

POD FREIGHT

Need support getting product to a Pod DC? Email us at inventory@podfoods.co for a freight quote!

IMPORTS

Neither Pod Foods nor its warehouse partners will serve as the Importer of Record or the Consignee for any shipment entering the US. No exceptions.

SHIPPING VIA CARRIER (PALLET)

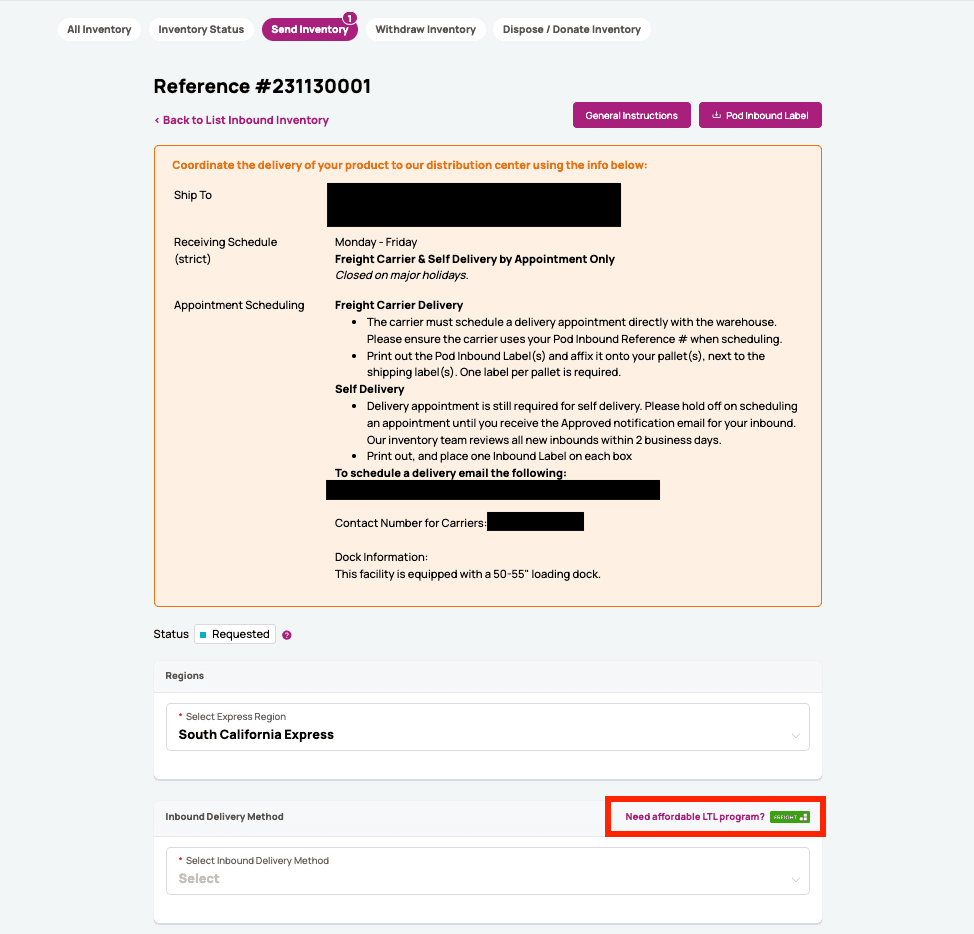

Step 1

Receive, view and complete your Pod Planned Inventory Request

You’ll receive an email with a new Pod Planned Inventory Request

Navigate to your dashboard > Inventory > Send Inventory > select the Reference # to open the request

Open the request and enter the required information:

Expiration date(s)

Lot code(s)

Estimated date of arrival

Tracking (if you do not yet have tracking information, use “TBD” as the tracking number so you can complete the request. Return to the request and enter tracking information once obtained).

Click Update button at the bottom to confirm!

Make note of your Pod Inbound Reference Number. You’ll use this number on your BOL and when booking an inbound appointment. All shipments will be rejected without a reference number

Step 2

Retrieve your Pod Inbound Label and download the packing list

Print your Pod Inbound Label and affix one to each pallet

You must include a packing list - This is accessible in the inventory inbound page in your dashboard

Step 3

Schedule your inbound appointment with our DC. We’ll leave this one up to you and/or your carrier. Email the DC directly to arrange an inbound appointment for your shipment.

Instructions on how to contact each DC are outlined in the inventory request in your dashboard.

Step 4

Once your inbound appointment is scheduled, update your dashboard with your tracking information and a copy of your BOL.

Step 5

Await inbound inventory processing.

You’ll be able to view your inbound on your dashboard within 5-7 business days from the date your inbound was received at the warehouse. Inbound processing delays are common. You will be notified of any delays via email.

Step 6

Receive confirmation of available inventory

Congratulations! Your inventory has been received and processed. View your newly-available inventory on your

dashboard. Let’s make some sales!

Brands that elect to self-deliver product to any Pod warehouse are responsible for ensuring that their product is received according to their scheduled and confirmed delivery appointments. Any delivery appointments that are missed or late may result in late fees charged by that particular warehouse.

POD EXPRESS : INVENTORY MANAGEMENT & POLICIES

Activated Pod Express brands require inventory management as they are carried in our DC network. For brands that are carried in an anchor account, or that have specific questions related to inventory, please reach out to your dedicated category manager or brands@podfoods.co

One of the key differences between Pod and conventional distribution is our inventory management and requests. Pod regularly requests inventory from our brand partners to maintain sell-through volume with our retail partners rather than issuing a purchase order. As inventory is received, orders are placed, and payouts are processed with net30 terms - completing the flywheel. It is essential that brands are an active partner in managing healthy inventory levels by fulfilling requests in a timely manner.

NOTE: We strongly recommend instituting an inventory MOQ which will help ensure optimal fill rates. Please reach out to your dedicated category manager or brands@podfoods.co for help setting up an inbound MOQ.

Inventory Management

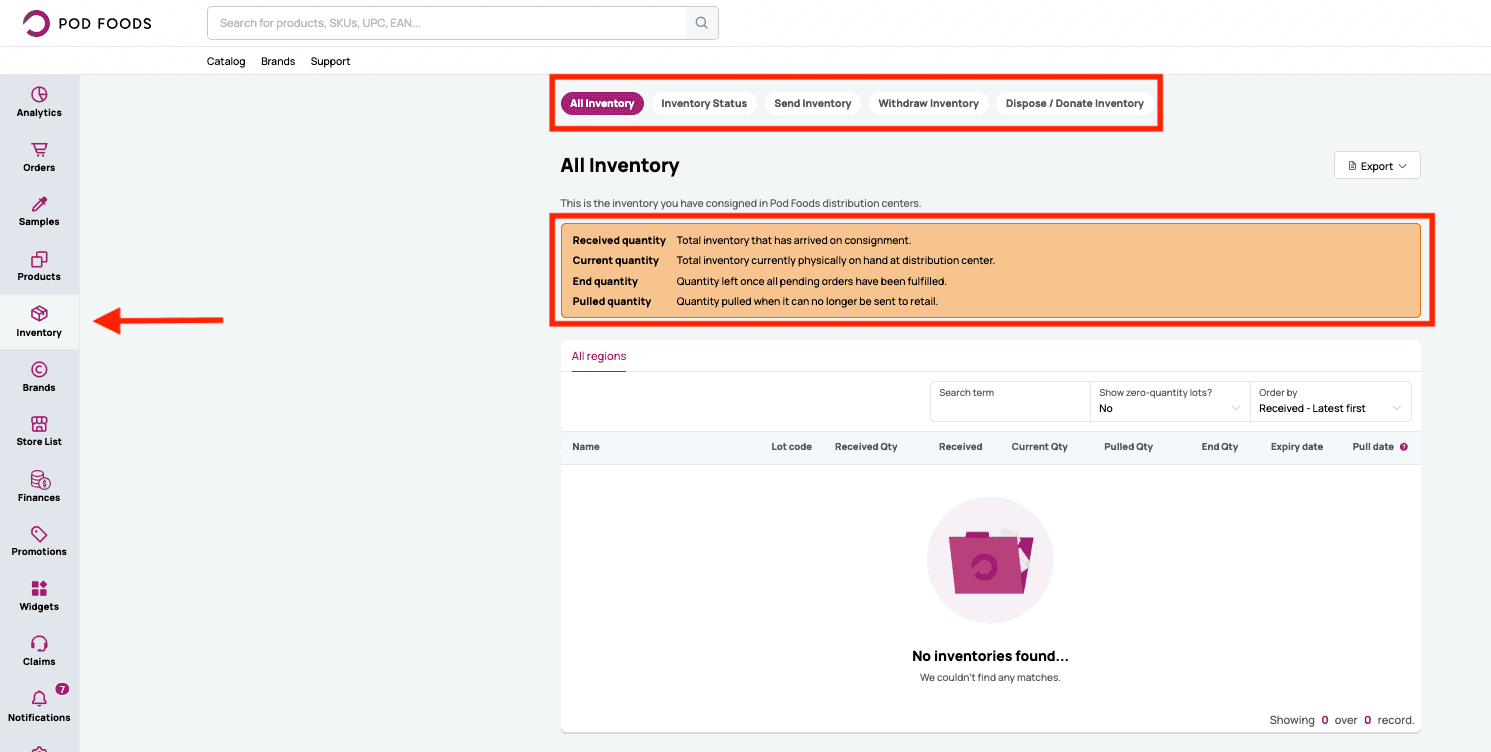

Navigating to the Inventory Tab

Click the “Inventory” tab in your vendor dashboard. This will present the main inventory page that details:

All Inventory

Inventory Status - Be sure to review by region for replenishment and sales insights

Send Inventory

Withdraw Inventory

Dispose / Donate Inventory

All Inventory

This is a detail of all inventory that is carried or has been carried in our DCs and tracked by lot codes

Received quantity

Total inventory that has arrived on consignment.

Current quantity

Total inventory currently physically on hand at distribution center.

End quantity

Quantity left once all pending orders have been fulfilled.

Pulled quantity

Quantity pulled when it can no longer be sent to retail.

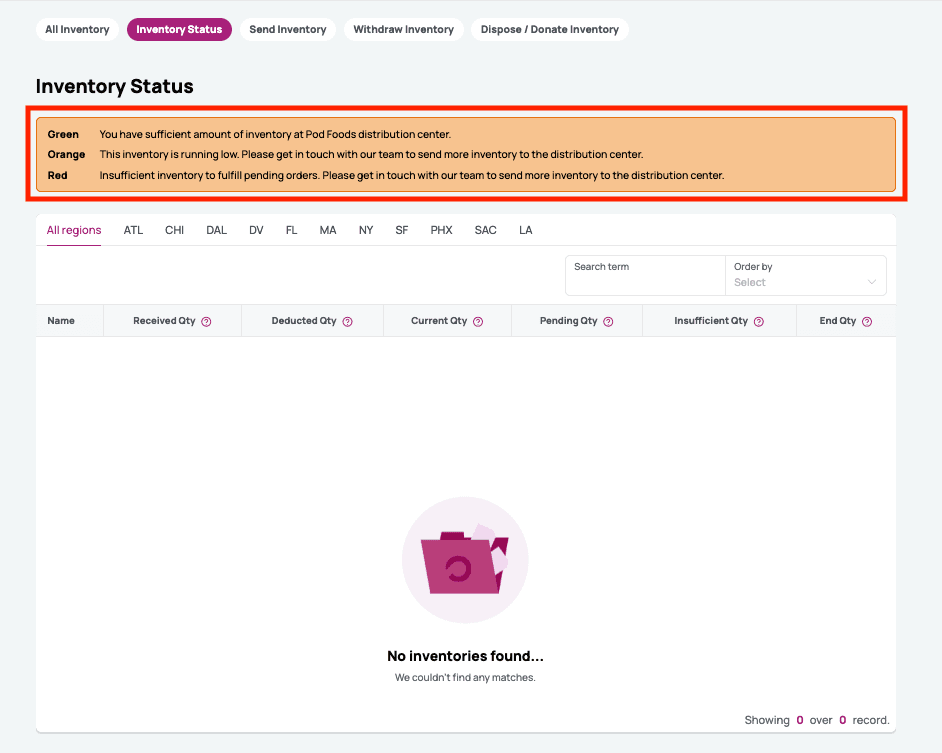

Inventory Status

This tool provides an at-a-glance assessment of your inventory health in each DC. It is strongly recommended to input an inbound inventory MOQ to ensure that safety stock is maintained and that fill rates are healthy. If you have any questions or would like to input an inbound inventory MOQ please reach out to your category manager or brands@podfoods.co

Green

You have sufficient amount of inventory at Pod distribution center.

Orange

This inventory is running low. Please get in touch with our team to send more inventory to the distribution center.

Red

Insufficient inventory to fulfill pending orders. Please get in touch with our team to send more inventory to the distribution center.

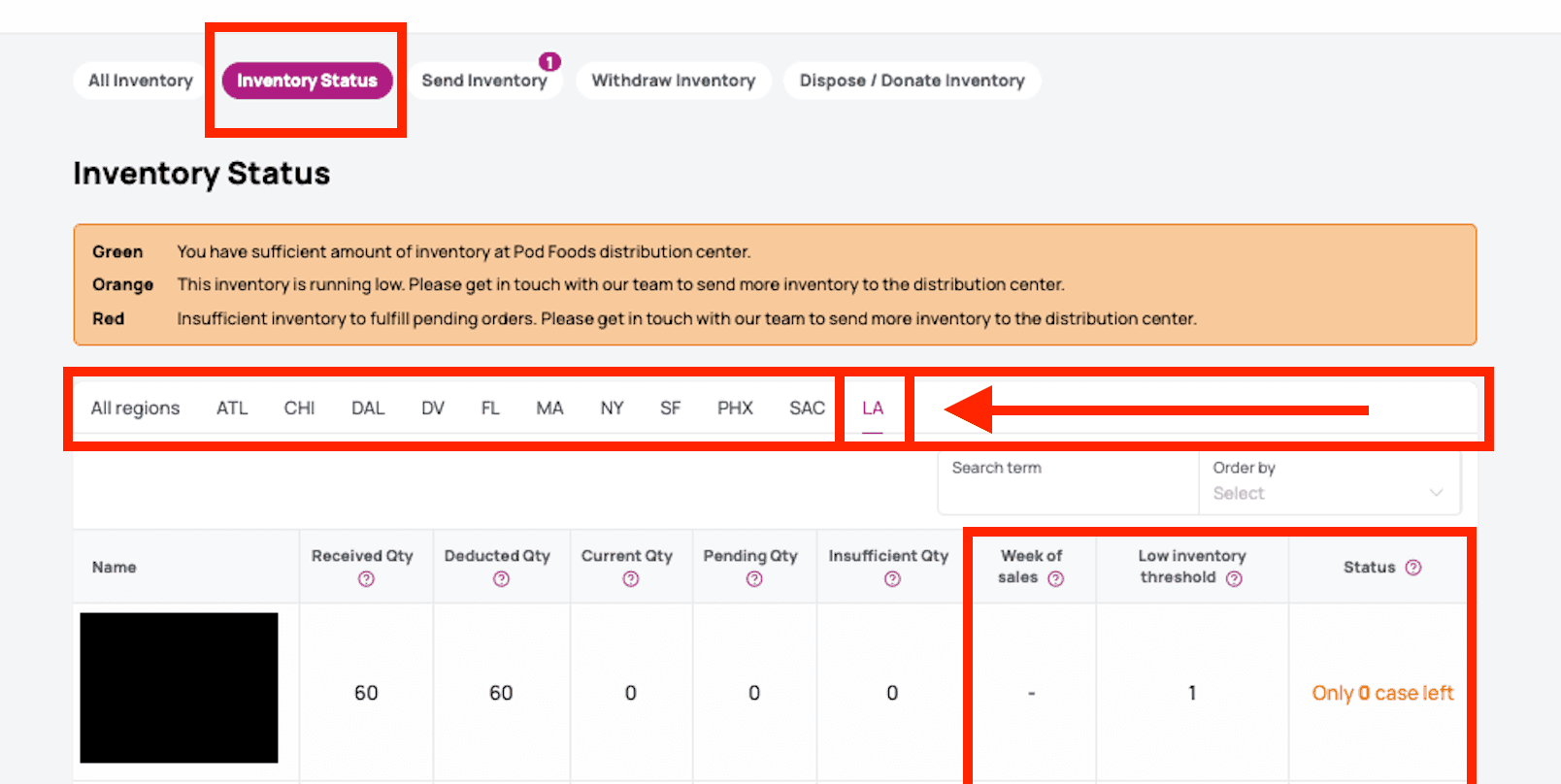

Regional Inventory Status

This section is essential to understanding your sell through and minimum inventory threshold requirements.

Please review by the specific regions your items are warehoused in for insights to:

WEEKS OF SALES - This is an estimate to how many weeks of sales your current inventory by SKU has within the DC based on historical sell through rates

LOW INVENTORY THRESHOLD - This is the minimum casepack count by SKU for healthy fill rates

STATUS - This is color coded and indicates healthy inventory levels (green), low inventory levels where replenishment is needed (orange), or insufficient inventory and risk of out-of-stocks (red)

We highly recommend instituting an inbound inventory MOQ to maintain healthy fill rates. Please email brands@podfoods.co to get one set up if you haven't already.

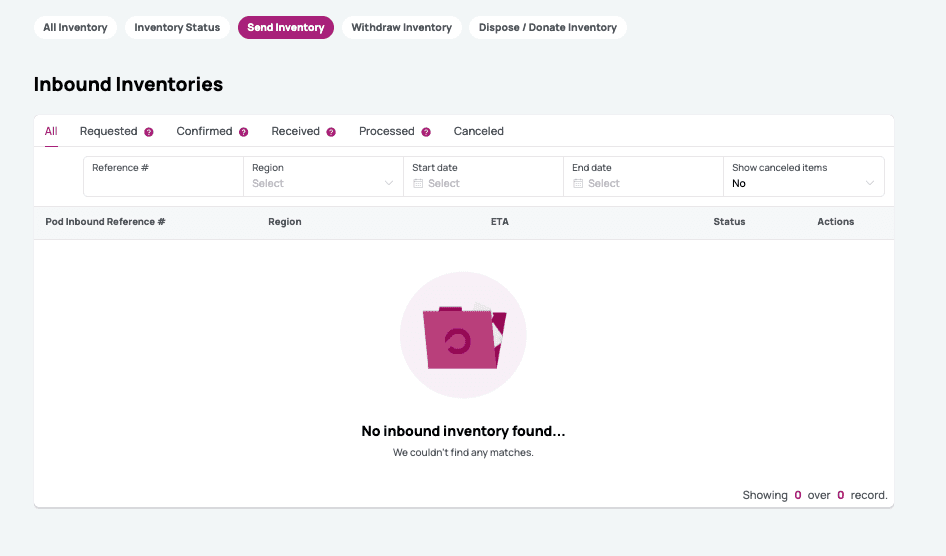

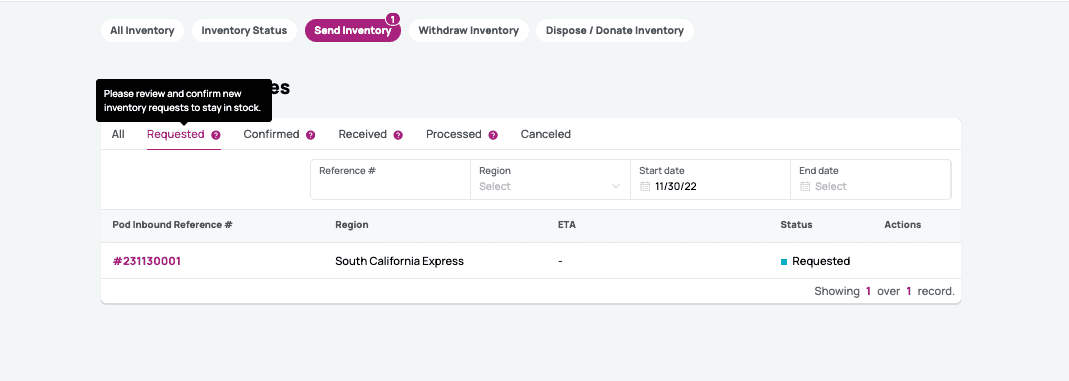

Send inventory after receiving a request

This is where Pod will provide inventory requests to your team. Please use this page to confirm inventory requests and track their status to our DCs. Please confirm inventory requests within one week of receiving them to maintain healthy fill rates.

Requested Inventory

Requested inventory will generate in the [Requested] tab and vendors are expected to review and approve the request within seven days to maintain optimal fill rates. Optimal fill rates are essential to your success as a brand.

Any instructions related to warehouse appointments are located in the inventory request. If the vendor wishes to add to the case counts, please email inventory@podfoods.co and cc your category manager or brands@podfoods.co and we will review your adjustment request.

Pod strongly recommends utilizing the Pod Freight program for inbound inventory. If you are interested in this please click here or email inventory@podfoods.co and cc your category manager or brands@podfoods.co

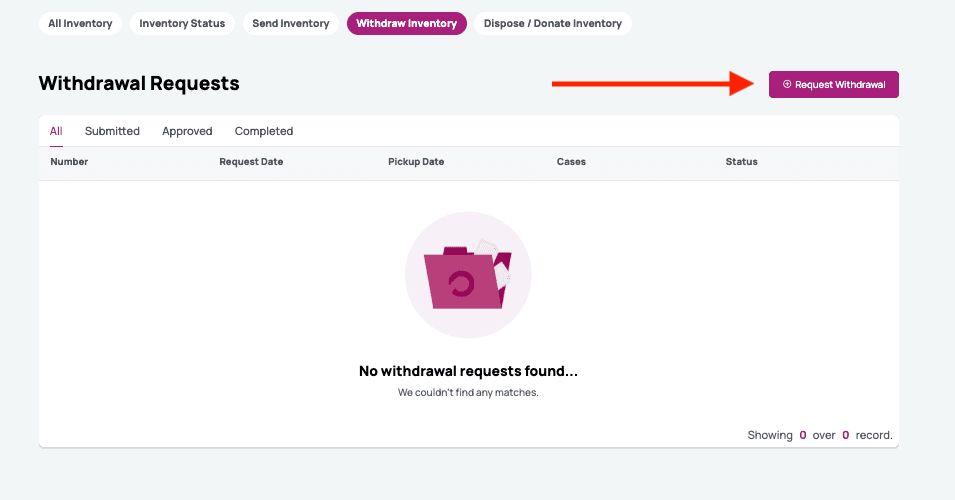

Withdraw Inventory

When withdrawing inventory, use this page to submit a withdrawal request. Each withdrawal request requires a pickup appointment.

INVENTORY POLICIES

Inventory Ownership

The vendor retains full ownership of their inventory until the product is signed by a store’s receiver upon delivery.

Each SKU in any Pod warehouse is expected to maintain a weekly GMV average of at least $50 per SKU over a sustained 12 week period. If sales for any given SKU falls below this sales threshold, it will be subject to removal from its respective warehouse.

Shelf Life

Minimum shelf-life for a Pod brand is 90 days.

Inventory must arrive at the DC with at least 75 percent of its total shelf-life remaining.

Expiration Date

Pod refers to printed expiration dates only. Vendor-suggested shelf life, alternative expiration dates, or other product dating-related information that differs from printed dates will not be taken into consideration.

Expiration Date Accuracy

Inbound inventory expiration dates must match the expiration dates submitted on the vendor’s original Pod Inventory Request.

The vendor must notify inventory@podfoods.co at least 24 business hours prior to inbound delivery if the expiration dates are expected to differ from the original request submission.

Inbounds that arrive with different expiration dates from the original request submission without prior notification from the vendor are subject to non-compliance fees.

Expiration Date Coding

Date coding must be clear and readable on both cases and units.

Cases and units must not be re-dated using stickers to conceal old or incorrect dates.

Date coding must be presented in human-readable format (e.g. YYYY-MM-DD).

Lot Coding and Traceability

All ingredients and finished products must be traceable for identification in the event of a recall.

The vendor must use a lot code or batch number system per each production lot.

Pull-Date Thresholds

Pod does not accommodate requests for pull date threshold changes outside of our specified thresholds. Thresholds are based on standard shelf life minimums required at store receiving:

30 days | 50 days | 90 days |

Chill | Hemp | VMS |

Your product’s pull date is calculated based on the expiration date you entered on your approved Pod Planned Inventory Request.

MAKING CHANGES + ITEM CODES

MAKING PRICE, CASE & PACKAGING CHANGES

Please refer to Product + Pricing Changes

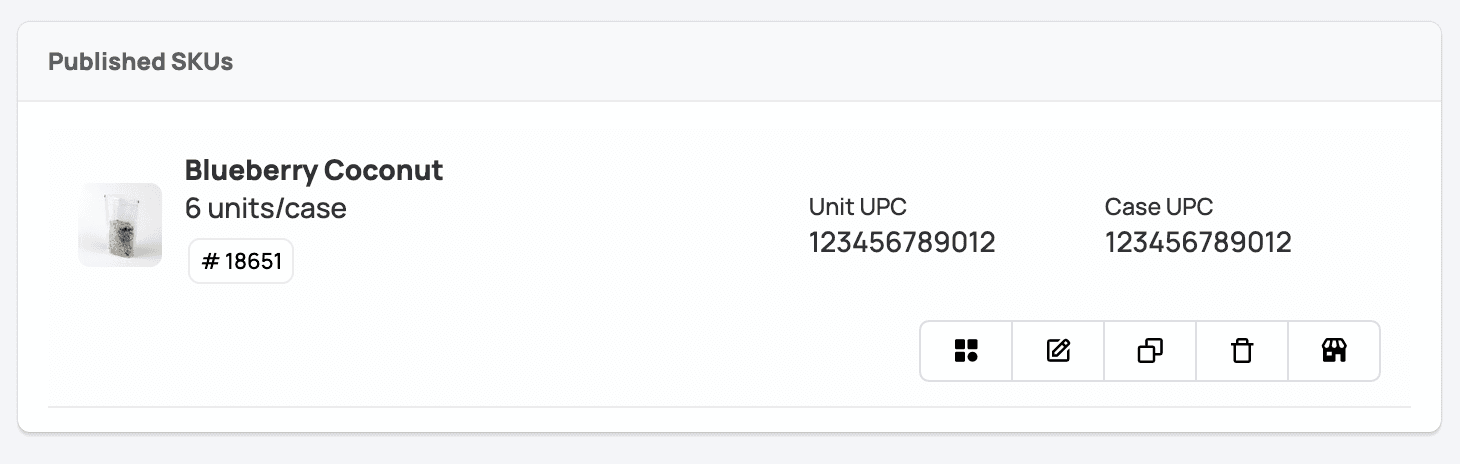

ITEM CODES

Item Codes are a unique identifier for SKUs that helps retailers search products and order with ease.

You can find your Item Code in your Vendor Dashboard > Products > SKUs > Item Code number is listed under each individual Published SKU (example: #17305)

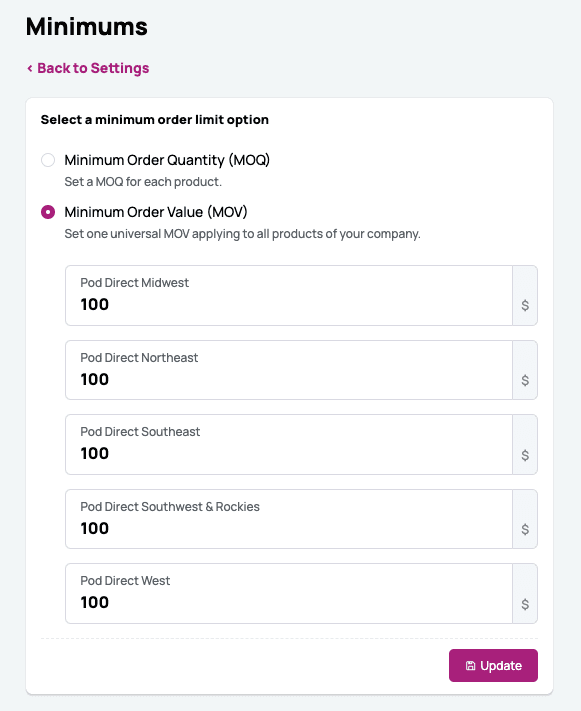

MINIMUMS

You control the minimums you ship

MOV - Minimum Order Value. This ensures that retailers can pick and choose across multiple product lines to meet your dollar-value-minimum for Pod Direct.

MOQ - Minimum Order Quantity – the MOQ that is set on the individual Product page applies to minimum case quantities per product. For instance, if it only makes sense for you to ship in quantities of four cases, you may elect to set the MOQ along with, for example, a $1 MOV.

When selecting a minimum - MOV will allow for a fixed dollar amount by region addressable within the same window. Setting an MOQ will require you to return to the unique SKU and apply a casepack minimum per SKU. Please use these instructions to manage your SKUs.

NON COMPLIANCE

Vendor noncompliance includes the following scenarios:

Late or unscheduled loads: Late or unscheduled shipments are subject to fees (if the load is accepted) or may be rejected entirely at receiving.

Appointment no-shows: Carrier no-shows are handled on a case-by-case basis. Fees may apply in certain situations and the appointment must be rescheduled.

Sort and segregate: Sort and segregate fees may apply to inbounds that arrive with significant damages or arrive as mixed pallets.

Short-dated inventory: Inventory sent with less than 75% shelf life requires prompt withdrawal from DC. Inventory sent with less than 45 days until expiration requires prompt withdrawal from DC. Vendor must initiate the withdrawal within 5 days of notification.

Expiration date discrepancies: Inbounds that arrive with different expiration dates from the original request submission without prior notification from the vendor are subject to non-compliance fees.

Detention: Pod is not responsible for detention fees incurred during inbound. The vendor and their carrier must settle detention fees with the warehouse directly.

Noncompliance Fees*

Noncompliance | Fee |

|---|---|

Late or unscheduled inbound | $150 |

Inbound appointment no-show | $150 |

Processing damages or discrepancies | $1.50 per case |

Incorrect Booking Details (palletized vs floor loaded ) | $150/Inbound Order |

Unscheduled /Late/Early Receipt | $150/Inbound Order |

Missing BOL/Parcel Tracking # | $100/Inbound Order |

Missing /Incorrect Inbound Order | $100/Inbound Order |

Missing /Incorrect Packing List | $100/Inbound Order |

*Non-compliance fees may vary by DC. The exact fees incurred will be communicated to the vendor by Pod, if non-compliance occurs.

CONSIGNMENT TERMINATION

Pod requires at least 60-days prior notice to terminate the partnership.

Notification of termination must be presented to Pod in written format (email).

Pod reserves the right to retain inventory on consignment to provide uninterrupted service to its retail partners.

POD DISTRIBUTION CENTERS

Pod maintains a national network of 9 regional distribution centers (DCs) to provide efficient, tri-temperature storage and fulfillment for emerging brands. Our strategically placed warehouses enable us to deliver products quickly and cost-effectively to retailers across the U.S., ensuring optimal speed-to-shelf for brands seeking to expand. Each facility is equipped to support seamless distribution to our retail partners.

Our 9 distribution centers are located in key markets, including:

Southern California (Carson, CA) - servicing the West Coast including Los Angeles, San Diego, and surrounding metro areas.

Sacramento (Tracy, CA) - servicing Northern California, including Sacramento, San Francisco, and surrounding metro areas.

North Texas (Dallas, TX) - servicing Texas statewide including Austin, Houston, and surrounding regions.

Denver (Aurora, CO) - servicing Colorado and the Mountain West metro areas.

Atlanta (Cartersville, GA) - servicing the Southeast, including Georgia, Florida, and neighboring regions.

Florida (Ocala, FL) - servicing Florida statewide and the Southeastern region.

Phoenix (Goodyear, AZ) - servicing Arizona and other neighboring metro areas.

Chicago (Aurora, IL) - servicing the Midwest including Chicago, Minneapolis, and surrounding regions.

Mid-Atlantic (Glen Burnie, MD) - servicing the Northeast and the Mid-Atlantic region including Washington D.C., Baltimore, and Philadelphia.

With this expanding network, Pod ensures brands have access to dependable storage, efficient fulfillment, and nationwide retail distribution. For further information on utilizing our DCs, please contact our support team.

Still have questions or feedbacks?

On this page